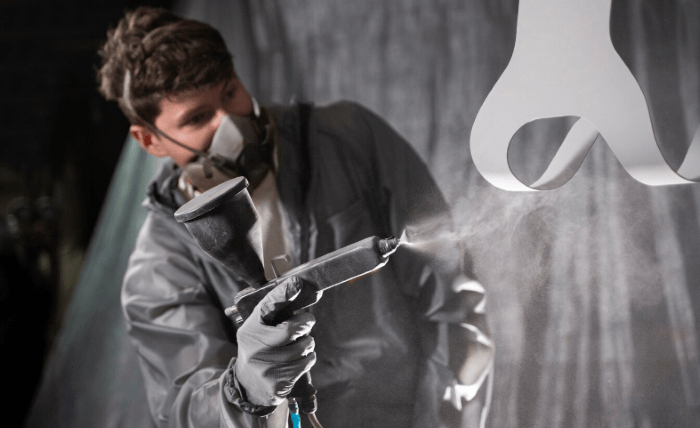

Anyone who’s spent time in a coating booth knows the difference between a flawless finish and a frustrating redo. Calibration isn’t just a technical step—it’s what makes a powder coating machine produce reliable, consistent results. If things start looking off, the equipment might be trying to say something.

Inconsistent Powder Adhesion Across Component Surfaces

A powder coating machine that’s not calibrated right can leave behind patchy coverage that looks uneven no matter how steady the hand. Adhesion problems often show up as areas where the powder clings in some spots but slides off others. Even with proper grounding and surface prep, if the electrostatic charge isn’t distributed evenly, the powder just won’t stick the way it should. This inconsistency can ruin a full batch, especially on complex parts with grooves or corners.

Technicians might try to compensate by spraying heavier or adjusting angles more than usual—but that’s not fixing the core issue. Proper calibration ensures the right flow of powder, voltage, and air pressure from the start. Without it, the powder coating machine becomes unpredictable, and time gets wasted chasing a result that should’ve been dialed in from the beginning.

Surface Defects Due to Erratic Electrostatic Output

Surface problems like bubbling, clumping, or excessive texture often trace back to poor electrostatic regulation. A coating gun that produces unstable output can cause uneven powder attraction, leaving behind finishes that look rushed or unfinished. These defects aren’t always immediately visible under booth lighting, but they become obvious after curing—right when it’s too late to fix easily.

Instead of blaming humidity or substrate prep, check the electrostatic control on the powder coating machine. If the voltage isn’t steady, the powder won’t lay uniformly, and the film build could shift from spot to spot. That subtle inconsistency turns into visible flaws after the part goes through the oven. Regular calibration helps avoid this cycle, keeping the finish smooth and the rework minimal.

Uneven Cure Profiles Resulting from Temperature Variance

Even if the powder goes on right, curing can take a wrong turn. A miscalibrated powder coating machine with temperature fluctuations—especially in integrated systems that include ovens—can create uneven cure profiles. This often leads to one end of a part finishing correctly, while another section remains undercured or overbaked.

This doesn’t just affect the look; it damages performance. Undercured powder won’t bond fully, making it prone to chips and scratches. Overbaking dulls color and weakens the coating’s toughness. If different batches keep producing inconsistent finishes, it’s time to check temperature sensors and control systems. A well-calibrated setup ensures the entire part gets the right cure every time.

Excessive Powder Overspray Causing Material Loss

Too much powder floating around the booth isn’t just messy—it’s money flying into the air. Excessive overspray often signals a powder coating machine that’s off balance in terms of airflow or pressure control. Powder that misses the target or gets blown away means higher material costs and more time spent on cleanup.

Calibrating air pressure and flow rates ensures powder lands where it should, reducing waste without sacrificing coverage. Overspray also creates problems for recovery systems, which can clog or wear out faster. By tuning the machine properly, operators can cut costs, improve transfer efficiency, and avoid clouding up the booth with wasted product.

Color Deviations Indicating Gun Voltage Fluctuations

Color shifts between parts of the same batch can throw off a whole production line. If a blue starts looking like two different blues under daylight, it might be the voltage. A powder coating machine that isn’t calibrated can deliver inconsistent charge levels, which affects how the powder is attracted and deposited on the surface.

Even subtle voltage drops or spikes can change how densely powder particles cling to metal. This leads to uneven light reflection once cured, and that means the color doesn’t look uniform. In industries where color matching is critical, this kind of inconsistency can mean rejected parts and lost time. Calibration keeps voltage stable and results predictable.

Reduced Coating Durability from Irregular Film Build

Coating thickness matters more than many realize. If the powder coating machine isn’t properly dialed in, the film build can vary from part to part—or even across a single piece. Too thin, and the finish won’t protect against corrosion or wear. Too thick, and it could crack during use or look blotchy.

Irregular film builds often come from unbalanced powder flow, poor gun settings, or inconsistent powder delivery. This kind of flaw usually shows itself later, after parts go into use or shipping. Consistent calibration avoids these durability issues by making sure the powder is applied at the right thickness across all surfaces, every time.

Increased Powder Consumption Without Production Gains

Using more powder than usual without an increase in finished parts? That’s a red flag. A miscalibrated powder coating machine often compensates for internal inefficiencies by pushing more material, rather than applying it smarter. It might seem like the machine is just working harder, but it’s actually being inefficient.

This kind of overuse quietly adds up. Higher powder use means more frequent refills, more downtime, and more strain on recovery systems. It also increases wear on the application equipment. A properly calibrated setup keeps consumption in check, helping operators get consistent results while keeping costs under control.